Dust Collector Fan Curve

In reality proper pipe sizing can get complicated and depends on many variables.

Dust collector fan curve. Cincinnati fan 200s t1 portable dust collector 2 hp 3450 rpm 1 phase 115 208 230v tefc enclosure black gray white 4 0 out of 5 stars 1 1 335 51 1 335. There is a large amount of misinformation about what the proper size pipe is to run. Tool size air requirements length of pipe run required number of machines running at one time etc. The ideal inlet for that 14 impeller is 10 from my fan table on the dust collection basics page.

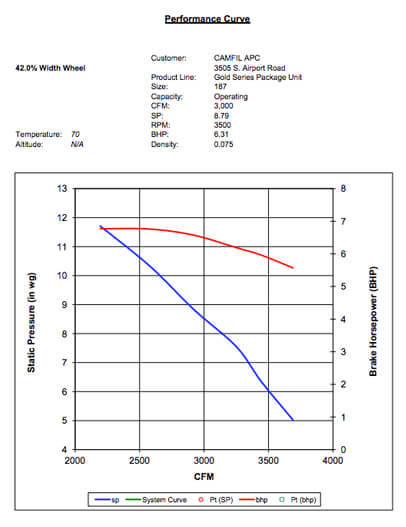

But that same table tells me at that big of an opening my horsepower will go way over for my budget motor that only has a real 3 hp. I tested and found that with the leeson motor 14 diameter impeller and cyclone that i can use up to a 7. The donaldson torit backward inclined fan is a convenient and cost effective way to integrate a high efficiency fan with a high quality dust collector. So using this information i looked at the performance curve for my dust collector.

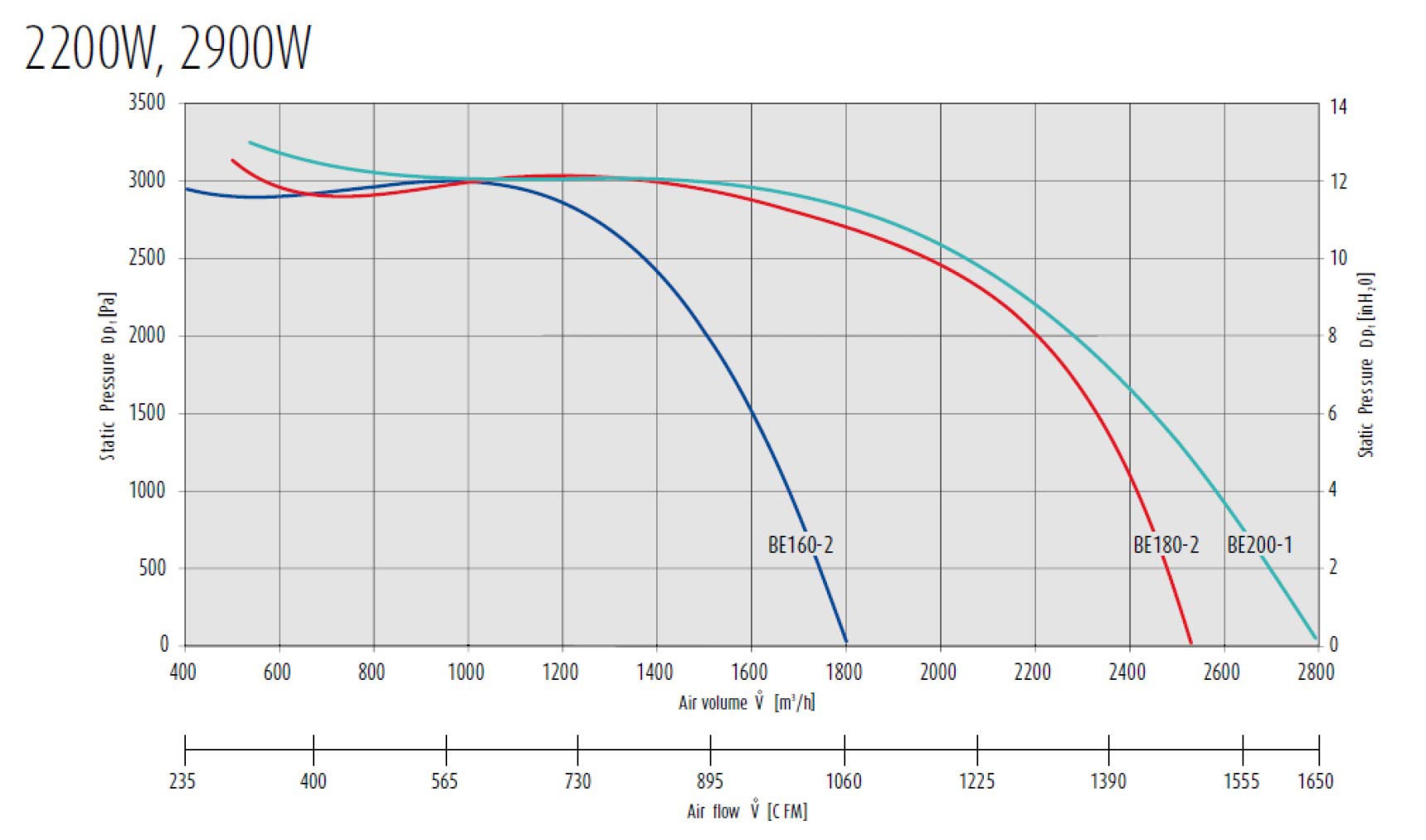

Available in models hdaf sqaf and cpaf blowers. A fan curve will show you how much cfm the dust collector will provide at any given static pressure which can be calculated base on what ducting hose is connected to the system. Being able to read a fan curve will allow you to choose the best fan for your requirements as long as the fan is properly tested and certified. Tbi fans are available in sizes ranging from 3hp to 30hp.

The first thing to note about the fan curve graph is that it has 3 axes. They are commonly used for ventilation forced cooling at higher pressures and on dust collectors where the fan is on the clean side of the collector. The fan mounts directly to the clean air plenum of the dust collector eliminating costly transition ducting. One of the popular dust collectors is the harbor freight 2 hp unit.

Airflow performance through static ductwork. Doing the same thing with the 10 3 the graph shows 625 cfm. I found the 8 5 and went across to the curve and then down to the axis and it says that my flow was about 950 cfm. Click here to learn more about sizing your ductwork.

Many dust collection systems suffer due to poor ductwork designs.