Fiber Optic Conduit Specifications

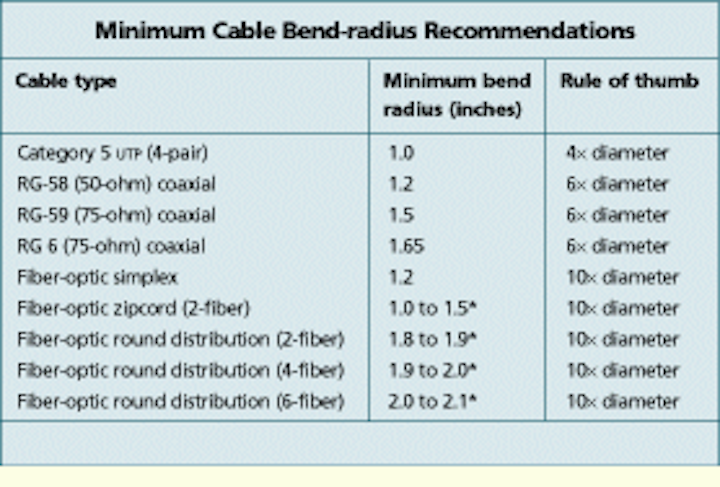

And always use a swivel pulling eye because pulling tension will cause twisting forces on the cable.

Fiber optic conduit specifications. Combination of rus form 515c and rus form 515d. All conduit is manufactured in accordance with astm f 2160 nec article 830. Number of 90 degree turns. Pulling underground fiber optic cable.

Underground fiber optic cable installations legal survey requirements required permits etc. G review and or comment on the overall project designs and or constructions by fortisbc does not. Specification for installation of underground conduit systems document no. Tremendous growth occurred for the installation of fiber optic cables during the early to mid 1980s for linking major metropolitan areas.

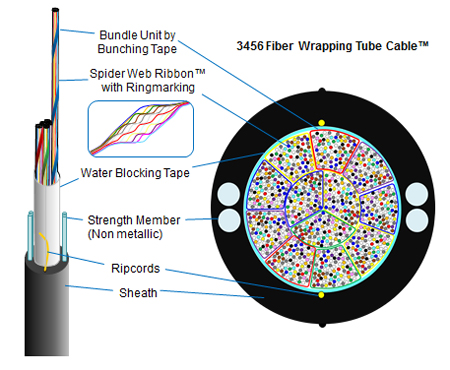

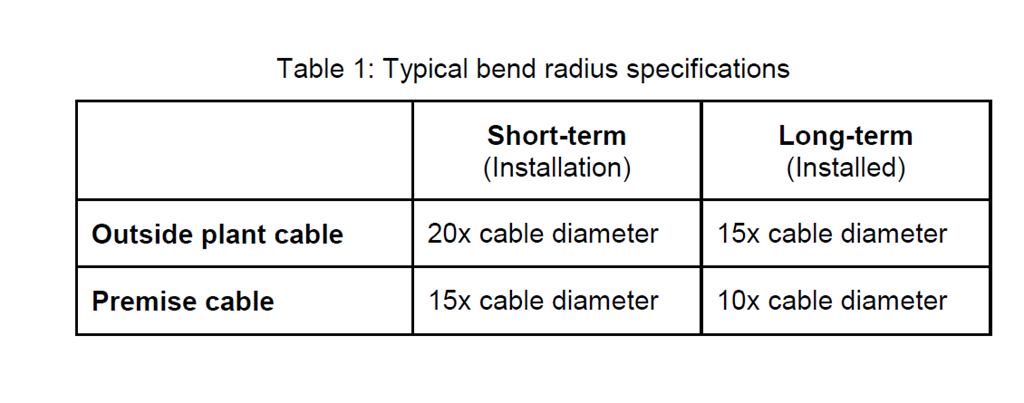

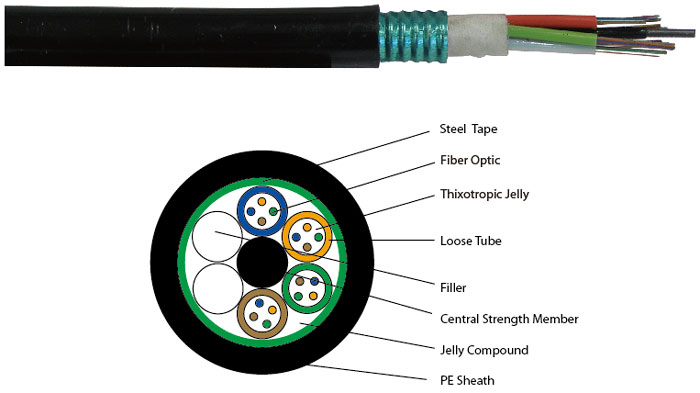

Fill ratios are calculated by comparing the area of an inner diameter cross section of the innerduct to the outer diameter cross section area of the fiber optic cable. The soil or encased in concrete. 683 921006na single mode fiber optic trunk cable and fiber optic drop cable. Special fiber optic blocks should be used on all turns or angles.

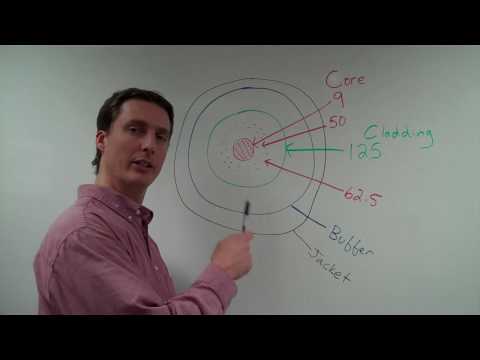

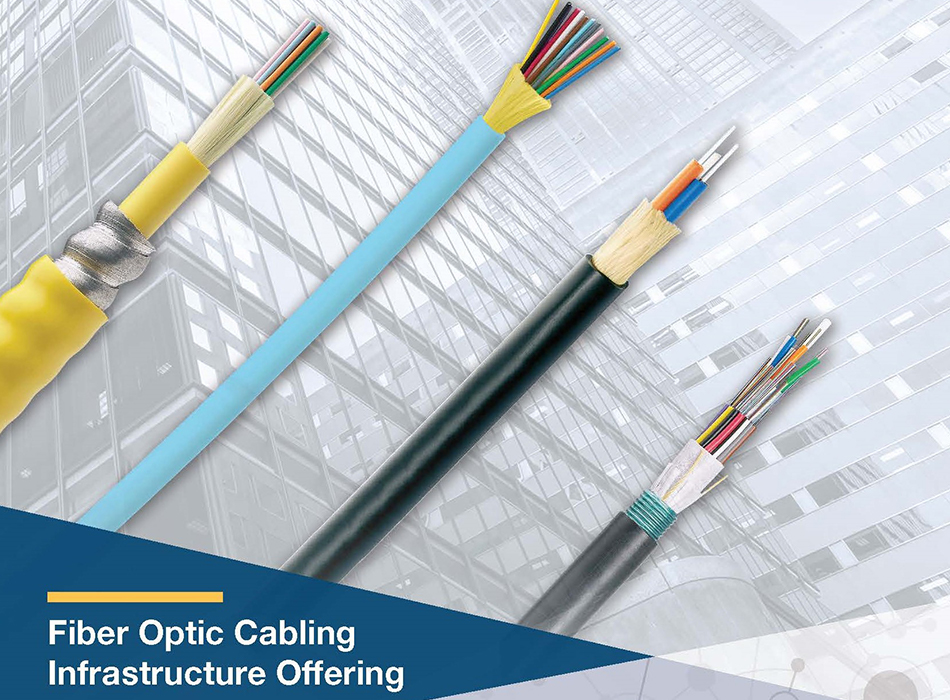

A fiber optic cable also known as an optical fiber cable is an assembly similar to an electrical cable but containing one or more optical fibers that are used to carry light. Bulletin 1753f 151 page i list of changes 1. 683 923024od fiber optic cable aerial 24 fibers. Duct and conduit products used to house and protect fiber optic and metal cable in the telecommunications catv and electric power industries.

Some of these products include smoothwall ribbed wall corrugated aerial figure 8. Carlon offers the widest range of products to meet all your application and specification needs. Corning optical communications fiber optic cable is compatible with all major brands of innerduct. Fiber optic cable plant manholes underground cable physical plant underground conduit specifications and standards.

Standard conduit is black hdpe and made in accordance with the requirements nema tc 7 astm 3485. 683 930100na dynamic message sign dms full matrix full color front access led. The optical fiber elements are typically individually coated with plastic layers and contained in a protective tube suitable for the environment where the cable will be deployed. The number of 90 degree turns on a pull shall not exceed 6 for aerial cables and 4 for underground cable in conduit.

Fiber optic cables have provided a more optimal use of available underground conduit space because of its small cable diameter and the much higher communications traffic capacity of each cable. Optical cable is usually placed in a 25 to 40 mm inside diameter id sub duct which is placed. 683 935001al wireless broadband communication system general specifications. Our tonable conduit is the reliable choice for locating dielectric optical fiber cables in hdpe conduit.

Modification of section hc to provide compensation on a.