Fiber Optic Cable Termination Procedure

Take the prepared end of the cable inside the splice van to maintain the temperature and dust free environment.

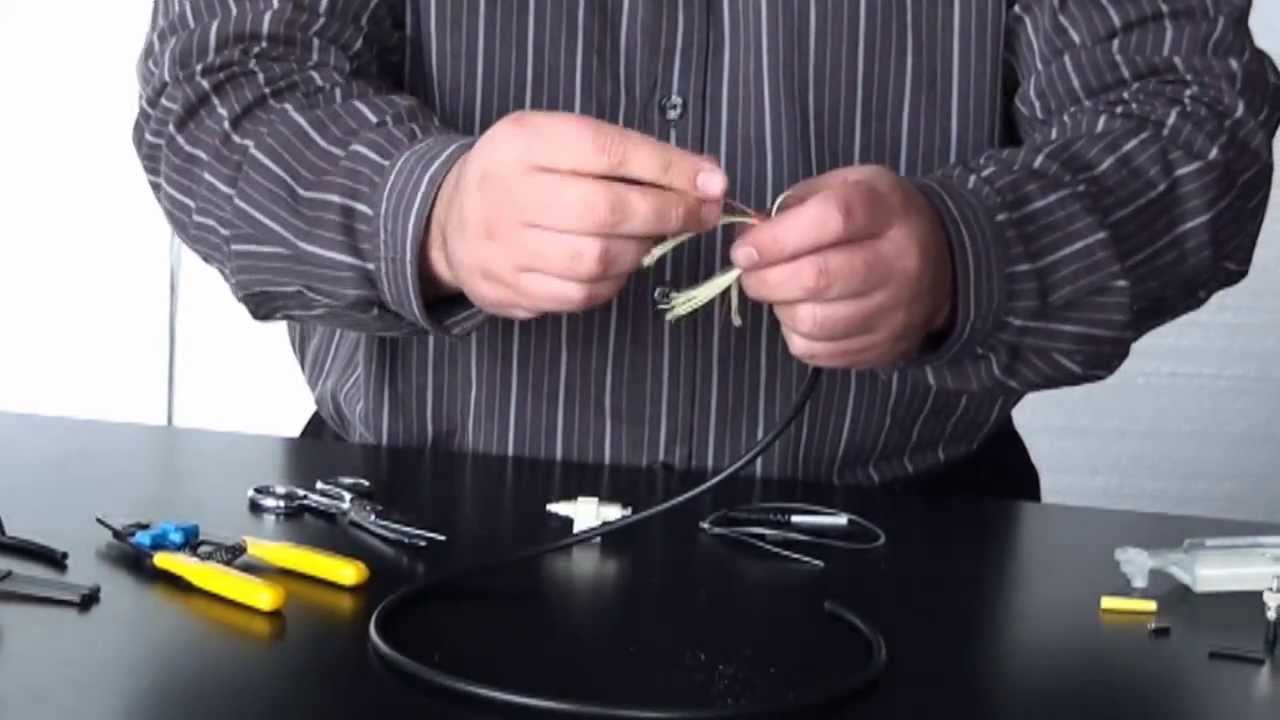

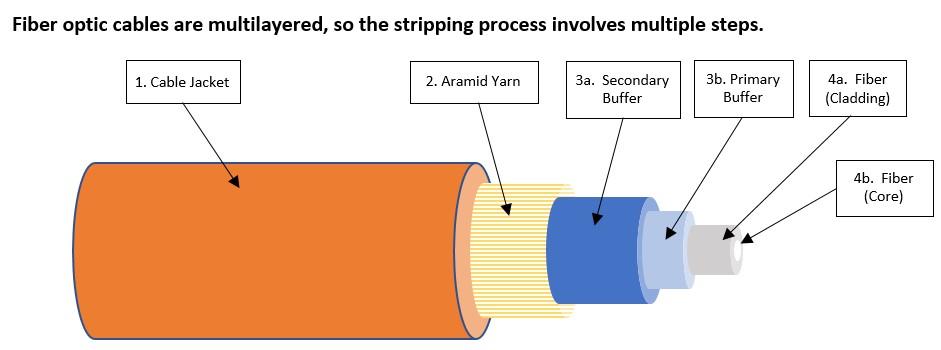

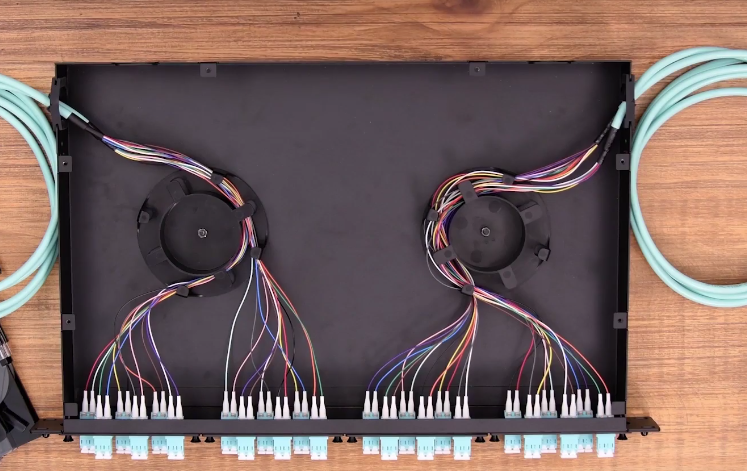

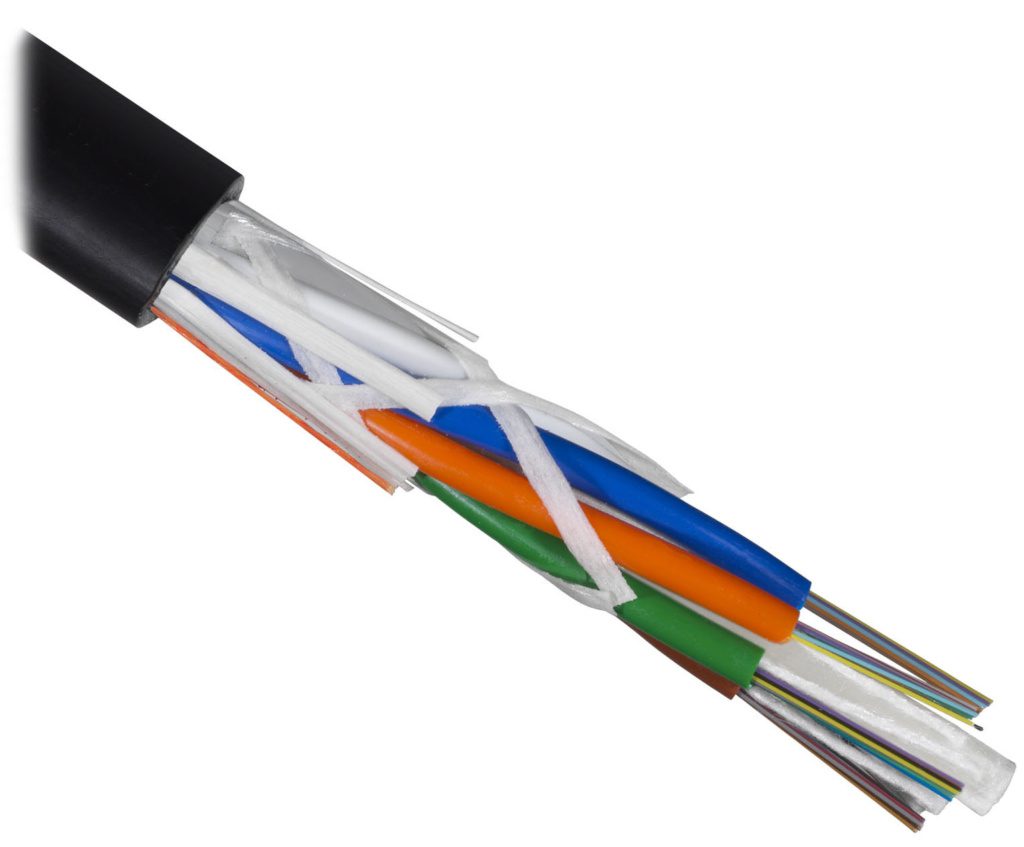

Fiber optic cable termination procedure. The reason for the termination is either to create a connection to a device or transceiver to splice two cables into one longer cable or to multiplex a cable so that it can move more branches. Prepare it for splicing or termination. Fiber cable is now ready for splicing and termination. We terminate fiber optic cable two ways with connectors that can mate two fibers to create a temporary joint and or connect the fiber to a piece of network gear or with splices which create a permanent joint between the two fibers.

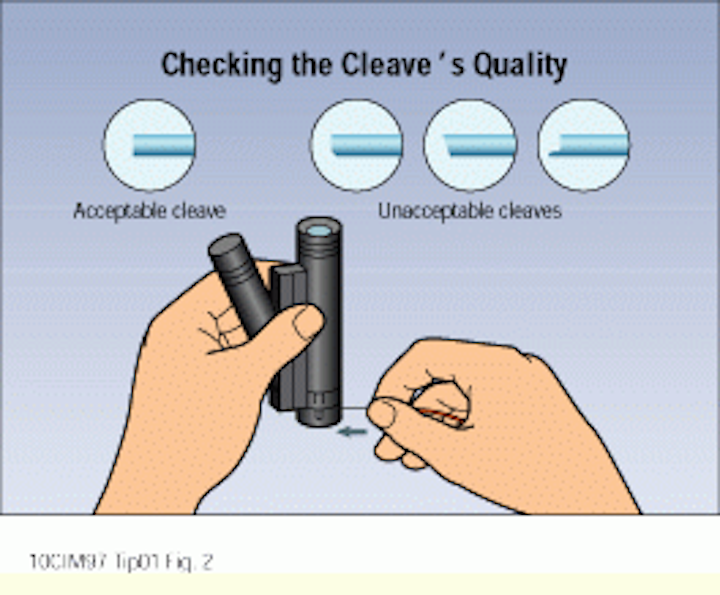

Turn on the splicer machine and then select the splice mode. This standard describes procedures for installing and testing cabling networks that use fiber optic cables and related components to carry signals. Prepare the fiber ends. Splicing is the other type and this involves connecting two bare fibers directly without any connectors.

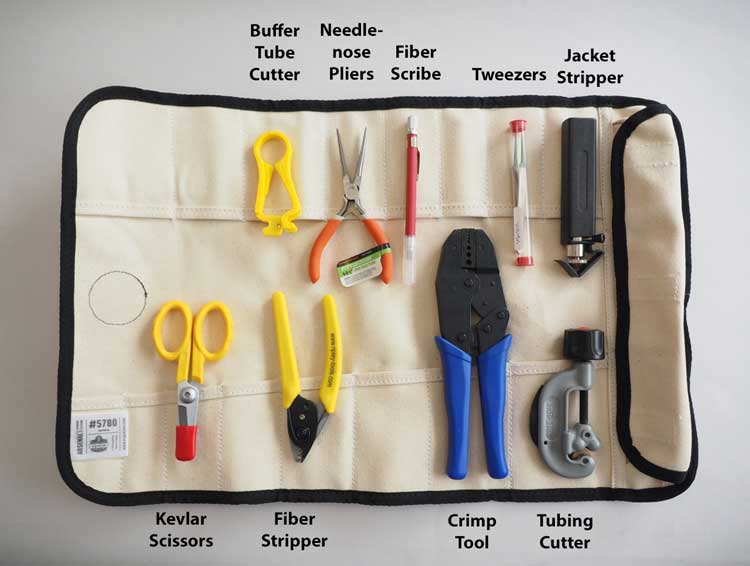

Fiber optic cables. The type of connector to be used in the termination depends on the type of cable and application. Splice the fiber optic cable to the factory made fiber optic pigtail. Before beginning the splicing operation secure the cable in an optical fiber splicer tray organizer.

Techopedia explains fiber optic termination. Two methods of fiber optic termination one type of fiber optic termination is the use of connectors that join two fibers to form a temporary joint. No area of fiber has been given greater attention than termanation. Fiber optic joints or terminations where cables are terminated are made two ways.

Make the otdr optical time domain reflectometer ready for testing. 1 connectors that mate two fibers to create a temporary joint and or connect the fiber to a piece of network gear left or 2 splices which create a permanent joint between the two fibers right.