Fatigue Testing Machine Diagram

Fatigue strength is thus of very great significance in machine design.

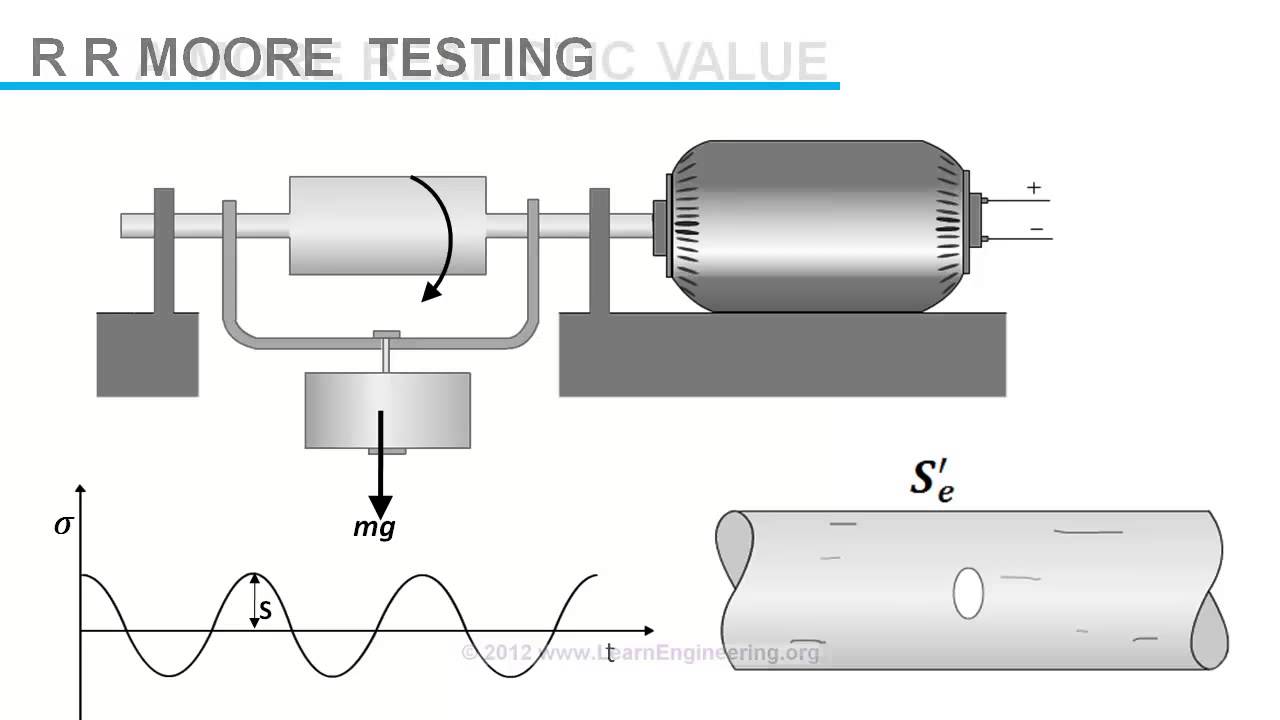

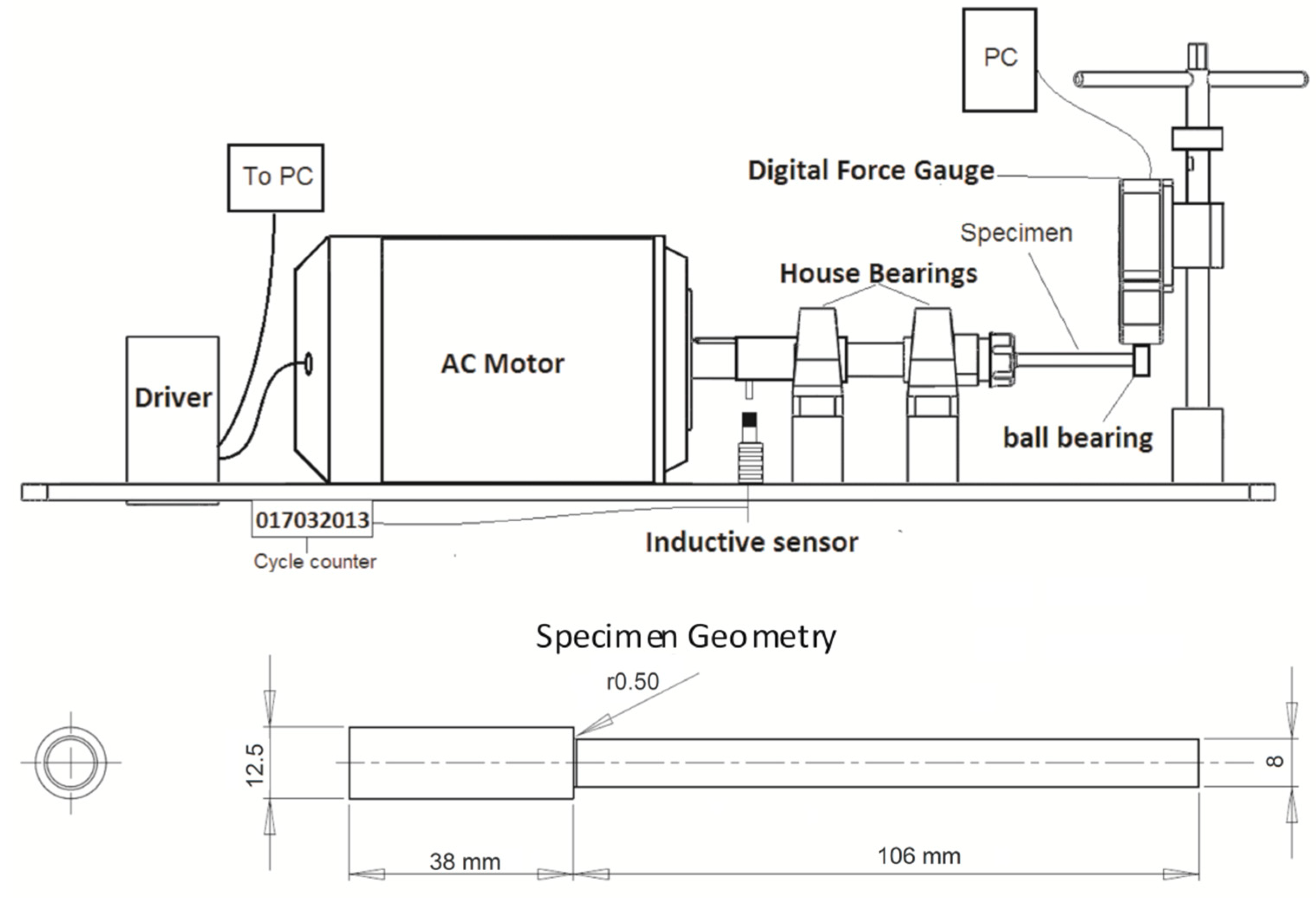

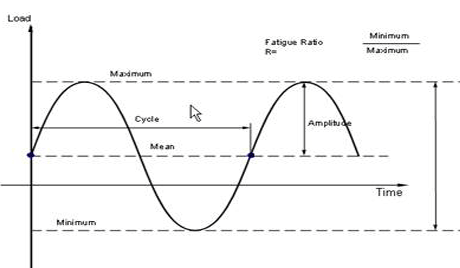

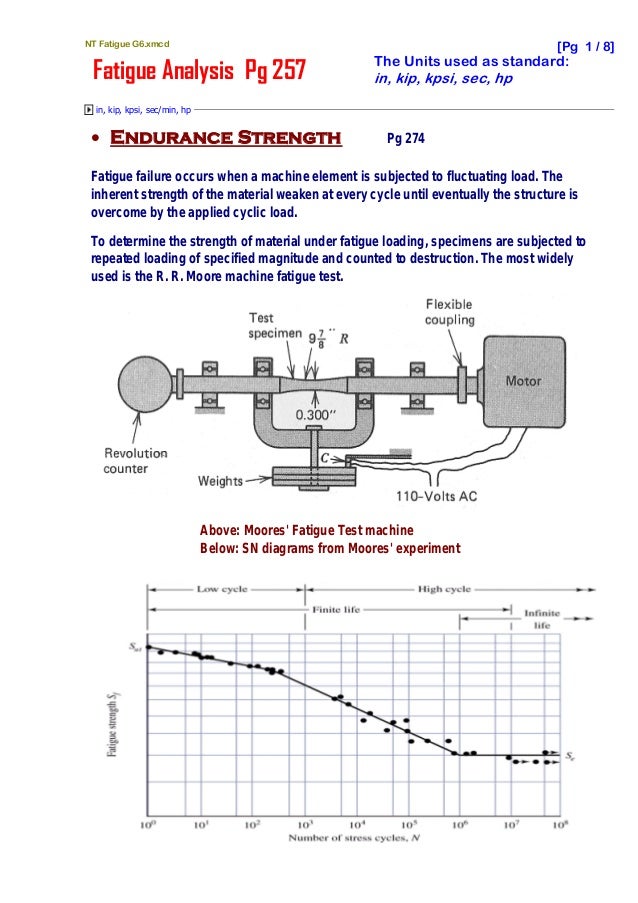

Fatigue testing machine diagram. Balaji fatigue testing machine capacity 200 kgcmthe machine is designed determining the fatigue properties of metals and alloys reverse bending cantilever type machine where the specimen is subjected to rotation at 2800 rpm with both ends held firmly between the gripping chucks with weights suspended through a lever. Rotating beam fatigue testing systems were first developed in the mid 1800s by a german railroad engineer named august wöhler. Fatigue tests are used on a range components from coupons through to full size test. Fatigue testing is a specialised form of mechanical testing that is performed by applying cyclic loading to a coupon or structure.

These tests are used either to generate fatigue life and crack growth data identify critical locations or demonstrate the safety of a structure that may be susceptible to fatigue. Mt3012 e fatigue testing machine with pc interface and software. He designed the machine to test railroad car axles and investigate axle brake failures. Electrodynamic testing machines are used to determine the durability of materials and components in the finite life fatigue and high cycle fatigue ranges.

Rotatory bending machine the purpose of the rotating bar bending fatigue test is to determine the bending fatigue strength properties under rotating load.