Engine Block Machining Process

Manufacturing process of engine block the end introduction we need to discuss.

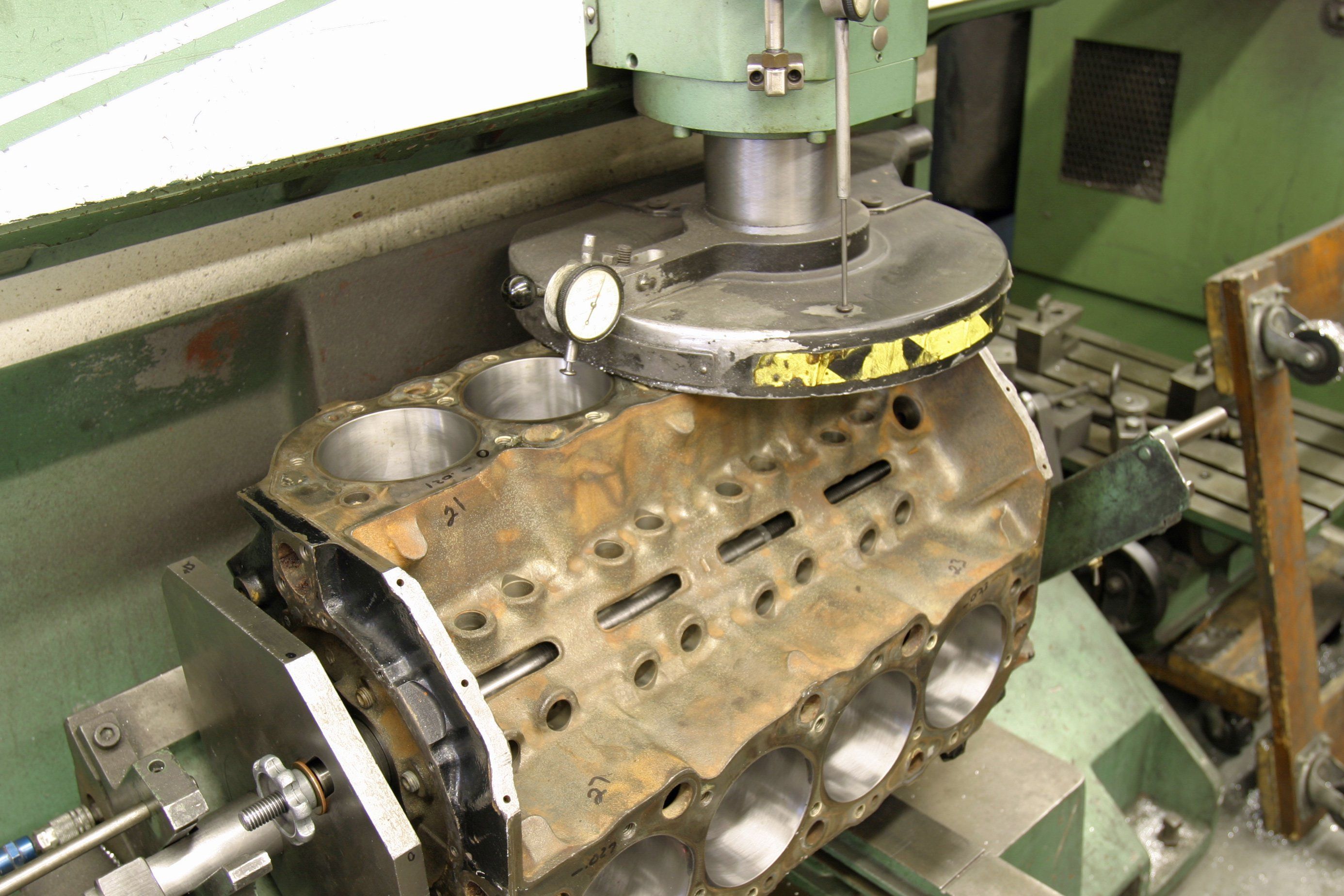

Engine block machining process. Many modern engines use cylinder blocks that consist of grey cast iron liners casted together with aluminium. A good inspection is essential early in the machining process to find any show stopping problems before any money is spent on parts. Engine block mel 202 manufacturing with metallic materials rohit anand 2013meb1108 under the guidance of dr harpreet singh asso professor smmee heart of the engine. Degreaser was sprayed on the block to aid the cleaning process which lasted 15 20 minutes.

Chase clean up the threads in all tapped holes. Engine block the engine block is a single unit that contain all the pieces for the engine. This extra procedure involves achieving a specific deck height and making both banks on. This makes machining engine block deck faces a considerable challenge.

Common machining tasks on an engine block involve deck resurfacing cylinder overboring to save a block or to increase displacement and cylinder honing. The block serves as a structural framework. In that regard the steps that any machine shop needs to perform on the block for any engine being rebuilt must include. Type of materials play an important role for the product in the end of the process.

The program objective of automotive engine block machining is to qualify the student as an automotive machinist. Eddie was in charge of all the hot tank runs block testing and prep for subsequent machining stations. Thus this the first installment in successful farming s three part series on hiring an engine machine shop services will explore proper block service procedures. Read more about bi metal machining process.

Because the block was an experienced used block keith recommended a good cleaning and degreasing followed by thorough inspection and magnaflux process to check for cracks. Coromill century bi metal machining process without burring chipping or scratching. Engine block manufacturing process introduction cylinder block which is also called as engine block is the main structure of the engine which give the space for the cylinders and it also give passages for the coolant exhaust and in take gases to pass over the engine and host for the crankcase and cam shafts. Engine block manufacturing process 1.

Conclusion manufacturing is the process of converting raw materials into products that is useful and ease our life. For high performance and racing applications this also involves an attempt to accurize a block an aspect of blueprinting.