Electrical Bus Bar Torque Specs

Have the bus bars cleaned annually with clean dry.

Electrical bus bar torque specs. The most common size used is 1 2 13 but 5 8 11 hardware is used for some very large joints and sizes. Knowing required ampacity determine possible bus bar dimensions from the table. All of the major companies who manufacture electrical components have torque specifications for their equipment ask for it. Up facilities engineering electrical interior facilities.

Ensure you know the torque specification. 882 853 3 way bus bar 876 199 terminal mount 901 325 red cover 3x m8 nuts assembly instructions place the battery terminal on the stud bus bar assembly for 2 positions bolt the two pieces together place z case fuses over standard fuse sizes. Diameter of bolt used should be compatible with hole in tang. Importance of torque in bussing a critical concept in understanding bus lug torque specifications is the fact that the pressure of the lug connection has more to do with lowering the resistance of the electrical connection than the size of the lug itself.

Use the torque specifications in. Bus bar and terminal connections. Ul test assembly procedures ul486a b. Then check table 1 to verify that size selected has the necessary ampacity.

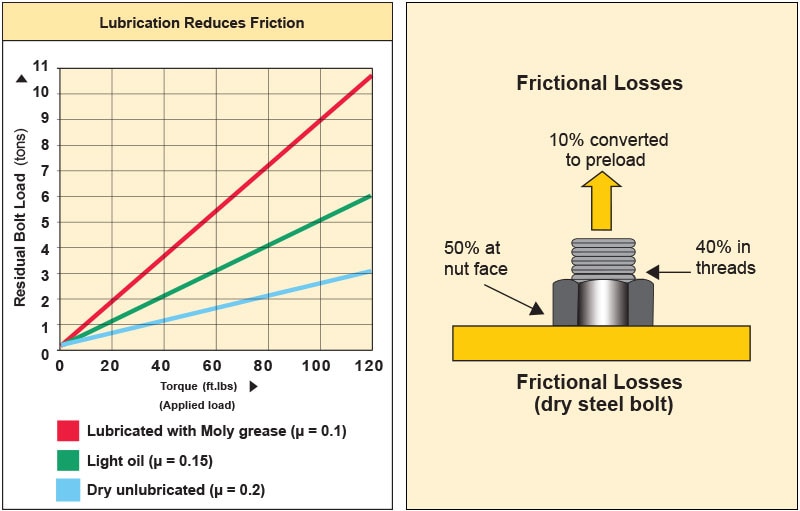

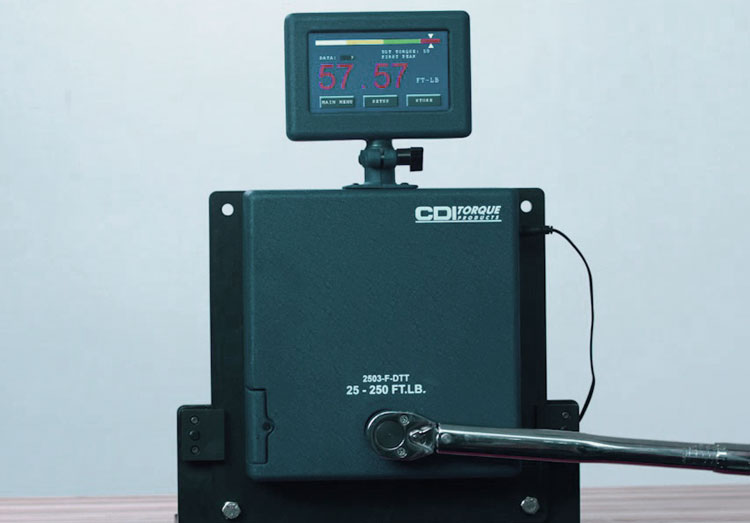

Hexagonal bolt grade minimum sae grade 2 unc coarse thread. Torque for bus bar lugs is specified by lug size. Ensure your electricians own and know how to use a torque wrench. For 60 hz current table gives bus bar cross sections which will probably be large enough for ampacities within each range.

Typical hardware for bolting listed lugs to bus bars. Tm 5 683 nawac mo 116 afjman 32 1083. Zinc plated to retard corrosion and installed with the proper torque this hardware has a long history of satisfactory performance with both copper and aluminum bus bars. Plated sae or stainless steel flat washers to be used on both sides.

I am a firm believer in using manufacture torque requirements i have been in the mining industry as electrical troubleshooter for 30 years and over 90 of failures caused by tightening methods i also will move the wire around and torque again this has proven to help in maintaining torque specs when wires are moved into position to close cabinet. Typical busway installation.